Introduction to Hydraulic Oil Pumps

A hydraulic oil pump is the primary power source in a hydraulic system. It converts mechanical energy into pressurized hydraulic energy. This energy drives the movement of actuators, valves, and hydraulic motors. Without the pump, the hydraulic system cannot perform its intended functions.

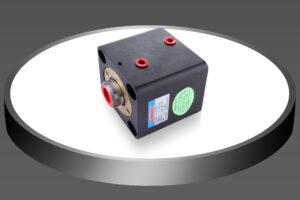

Main Components of a Hydraulic Oil Pump

The hydraulic oil pump typically includes four essential components. These are the pump body, a rectangular oil tank, a pressure handle, and a high-pressure steel braided hose. Together, these parts allow the system to pressurize and circulate hydraulic fluid effectively.

Function and Role in Hydraulic Systems

The pump’s main function is to supply pressure and flow to the entire hydraulic system. It delivers the necessary force to operate tools, machines, and devices connected to the system. It plays a critical role in maintaining stable system performance and reliability.

Common Structural Types of Hydraulic Oil Pumps

There are three common types of hydraulic oil pumps: gear pumps, vane pumps, and piston pumps. Gear pumps are compact and cost-efficient, suitable for low to medium pressures. Vane pumps provide smoother flow, making them ideal for moderate pressure systems. Piston pumps handle high pressure and are often used in heavy-duty industrial systems.

Connector Types Used in Hydraulic Pumps

Hydraulic oil pumps use various connector types to ensure secure fluid transfer. These include straight-through connectors, self-sealing connectors, and quick-connect fittings. Each type has specific advantages in ease of use, safety, and leak prevention. Selecting the right connector helps improve system reliability and maintenance efficiency.

How to Select the Right Hydraulic Pump

Selecting the right hydraulic oil pump depends on multiple factors. These include the required system pressure, flow rate, and operational environment. In addition, reliability, service life, and ease of maintenance should also be considered. A properly selected pump ensures efficient operation and reduces downtime in the long term.

Key Features of Hydraulic Oil Pumps

Hydraulic oil pumps are compact and lightweight, making them easy to transport and install. They support high working pressures, even in limited spaces. Single-stage pump stations are simple in design and deliver consistent performance. Dual-stage pump stations offer greater efficiency by combining high flow at low pressure and energy savings at high pressure. During high-pressure operation, the low-pressure pump automatically unloads, reducing unnecessary power consumption.

An important feature is their pressure-holding capability. When the external pipeline is sealed, the system can maintain pressure for five minutes after the pump stops. In such cases, the rated pressure drop remains within 5 MPa. This ensures temporary system stability without constant pump operation.

Conclusion

Hydraulic oil pumps are fundamental components that provide the power needed for hydraulic systems to function. Their design, connector types, and performance features vary depending on application requirements. By understanding how they work and how to choose the right model, engineers and operators can significantly improve the efficiency and reliability of their systems.

Pingback: Hydraulic cylinder care and maintenance tips

I stumbled upon this site while looking for reliable tech insights and I must say the quality of content here is impressive. It really helped me figure out which tools are actually worth my time without all the usual fluff. Thanks for sharing this aipilotreview