When designing hydraulic system oil tanks for large hydraulic systems, material selection is critical.

Corrosion-resistant steel is commonly used due to its durability and compatibility with hydraulic fluids.

The surface must undergo proper anti-corrosion treatment, both inside and outside the tank.

Material must also allow easy post-treatment processing and ensure economic production costs.

When conditions allow, using stainless steel is the ideal choice for hydraulic oil tanks.

A properly designed oil tank must meet several requirements:

• It must have enough capacity to absorb heat generated during system operation.

• It must contain the entire hydraulic fluid volume when the system is stopped.

• It must maintain an appropriate fluid level during system operation.

Therefore, the tank structure should meet the following key features.

Below are the main components and their design points.

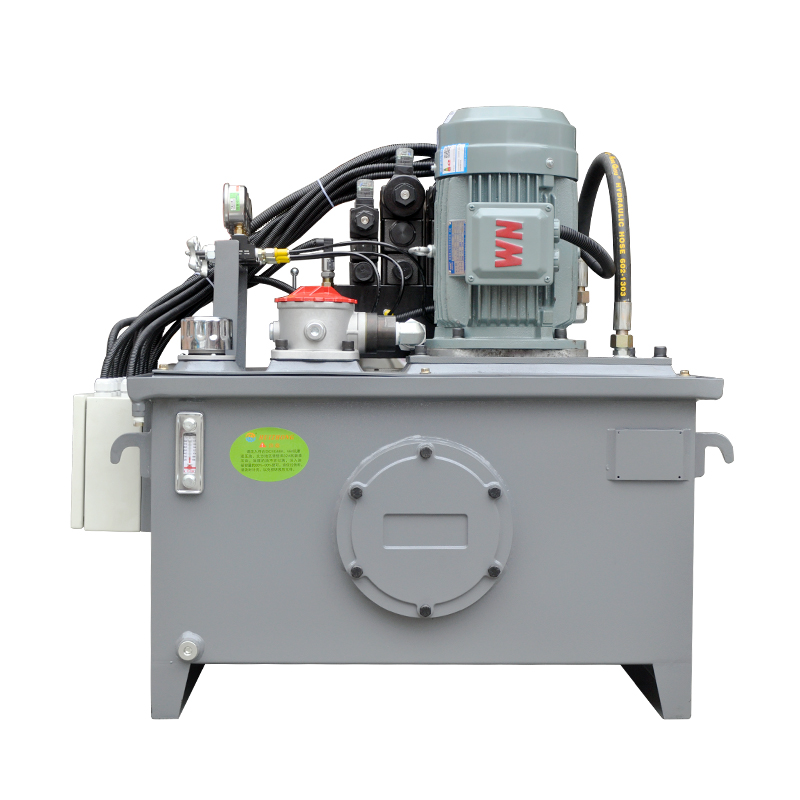

Hydraulic System Oil Tank Body

The tank wall thickness should be 3–4 mm for normal applications.

If the tank volume exceeds 320 liters, use 4–6 mm thickness for better strength.

An oil level gauge must be installed on the sidewall to monitor the actual oil level at all times.

Maintenance Covers

Install one or more maintenance covers on the sidewall of the tank.

Each cover should use sealing gaskets and bolts to prevent oil leakage.

The main purpose is to allow easy cleaning of the filter and internal tank surfaces.

Tank Bottom Structure

Design the tank bottom with a sloped surface welded to the side panels.

Install a drain port at the lowest point of the tank bottom.

This design ensures easy and complete draining of oil during maintenance.

Suction and Return Pipes

Both the suction and return pipes must extend below the minimum fluid level.

This prevents air intake and reduces bubble formation during system operation.

Pipe openings should maintain a distance of at least three times the pipe diameter from the tank bottom or sidewall.

This helps minimize fluid disturbance and maintain system stability.

Drain Pipes

Drain pipes are used to collect leakage oil from components like pressure control valves.

When designing, ensure that drain pipes do not extend below the oil surface.

Otherwise, backpressure could affect system performance and cause operating issues.

Final Thoughts

A well-designed hydraulic oil tank enhances system reliability, cooling efficiency, and maintenance convenience.

Always consider material durability, corrosion resistance, and ease of maintenance when selecting and designing tank structures.

For more technical insights about hydraulic systems, feel free to explore our website or contact our team for expert advice!

Pingback: Importance of Control Valves Selection for Hydraulic Cylinders - JinZhuang Hydraulic