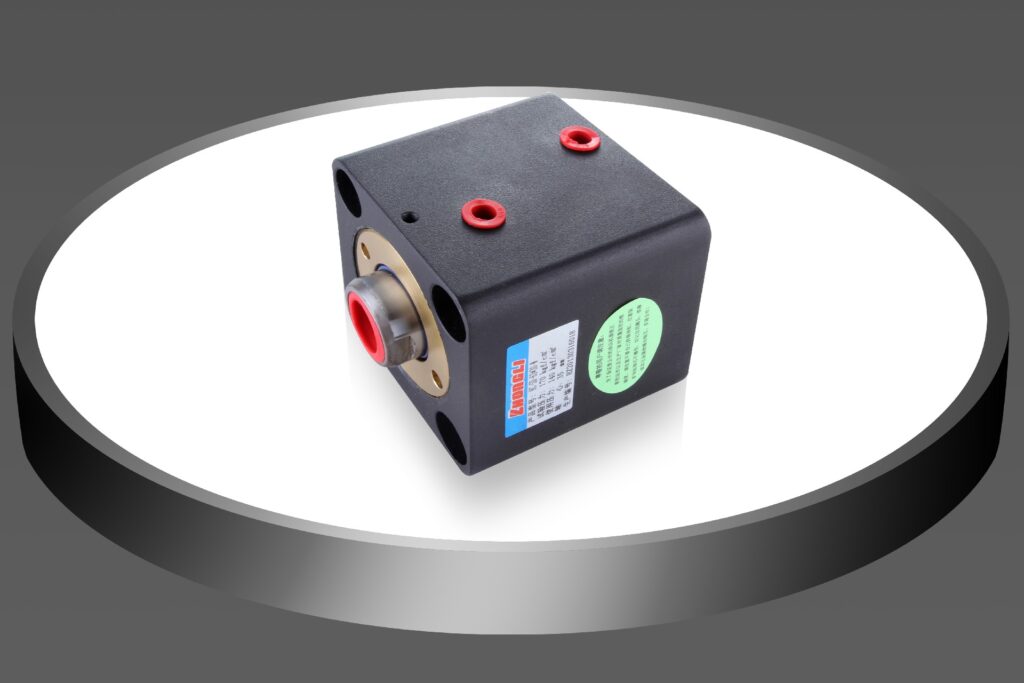

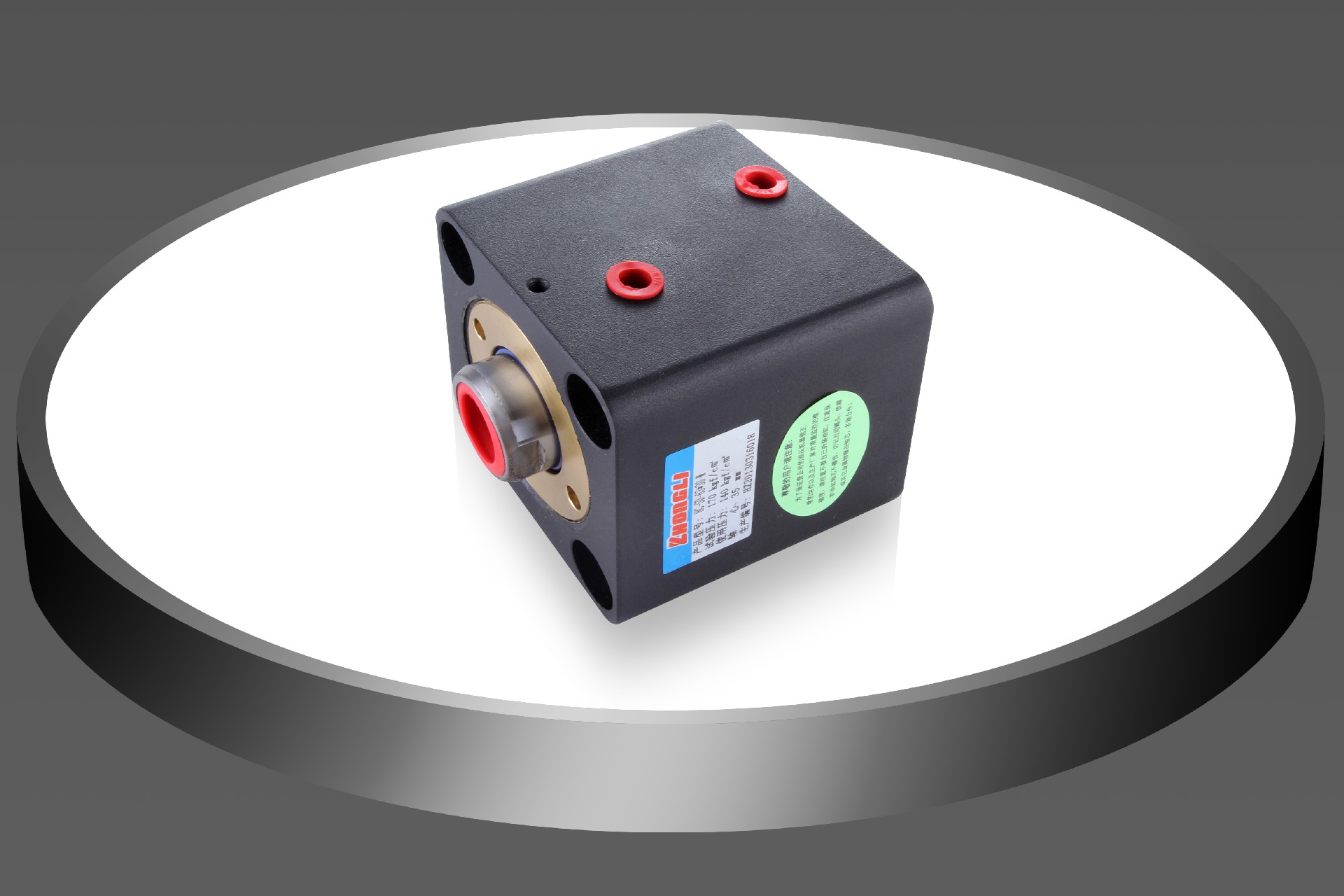

When maintaining or repairing HC thin hydraulic cylinders, it is important to follow the correct procedures. This ensures safety and protects all components from damage. Here are the essential steps and precautions during disassembly.

Release the Hydraulic System Pressure

Before disassembling the cylinder, always release the pressure from the hydraulic system.

If pressure remains, loosening a hose may cause high-pressure oil to spray out.

This can result in serious injuries.

To release pressure:

• Loosen the handwheel or adjusting screw on the relief valve.

• Allow the system to unload pressure completely.

• Shut off the power or hydraulic source to stop system operation.

Avoid Damaging Key Components

During disassembly, protect critical parts carefully:

• Piston rod threads

• Port threads

• Piston rod surface

• Inner wall of the cylinder tube

Use soft wooden blocks to support long parts like piston rods.

This prevents bending or deformation during handling.

Follow the Correct Disassembly Sequence

Different hydraulic cylinders may require different disassembly orders.

In general:

• Drain oil from both cylinder chambers.

• Remove the cylinder head carefully.

• Finally, disassemble the piston and piston rod.

Important Tips:

• For retaining rings, use specialized tools instead of chisels.

• For flange-mounted end caps, push them out using screws, not force.

• If the piston or rod is stuck, do not hit or pry them.

First, find and fix the cause before proceeding.

Prevent Dust and Contamination

During disassembly, work in a clean environment whenever possible.

Cover disassembled parts with clean plastic sheeting immediately.

Avoid using cotton cloths or rags that might release fibers.

Keep all parts free from dust, dirt, and other impurities.

Inspect Components Thoroughly

After disassembly, inspect every part carefully.

Decide which parts:

• Can be reused directly

• Can be repaired

• Must be replaced with new ones

A careful inspection improves system reliability and lifespan.

Clean All Parts Before Reassembly

Before putting the cylinder back together, clean all parts thoroughly.

Remove any oil residue, dust, or other contaminants.

Clean assembly improves sealing performance and system efficiency.

Install Seals Correctly

Proper seal installation prevents oil leaks and pressure loss:

• O-Rings: Avoid overstretching or twisting during installation.

• Y-Type and V-Type Seals: Ensure correct installation direction.

• Y-type lips should face the pressure side.

• Distinguish between shaft-use and bore-use seals correctly.

• V-Ring Assemblies:

Install them with the opening side facing the pressure.

Tighten the compression ring just enough to prevent leaks.

Apply a thin layer of hydraulic oil when installing seals that interact with sliding surfaces.

After disassembly, replace all O-rings and dust seals with new ones.

Tighten Threaded Parts Properly

Use a proper torque wrench or specialized tool when tightening threads.

Ensure the tightening torque meets standard specifications.

Avoid overtightening, which could damage parts, or undertightening, which could cause leaks.

Final Thoughts

Disassembling an HC thin hydraulic cylinder requires following strict safety and technical procedures.

By properly releasing pressure, protecting key surfaces, and maintaining cleanliness, you can ensure safe maintenance and extend equipment life.

For more professional guidance on hydraulic maintenance, please explore our website or contact our team directly!

Choosing the right control valve is crucial for hydraulic cylinder performance. Discover our detailed guide here.

Pingback: The influence of hydraulic cylinder quality on system performance - JinZhuang Hydraulic