Why Regular Maintenance of Hydraulic Equipment Is Essential

In daily operation, fatigue in hydraulic equipment is inevitable. To ensure long-term performance and safety, machines must be regularly shut down for inspection and maintenance. One critical component is the hydraulic cylinder seal, which demands professional care to extend its lifespan and improve sealing efficiency.

Inspecting the Hydraulic Support Cylinder for Oil Leakage

The piston of the hydraulic support cylinder plays a crucial role in preventing hydraulic oil leakage. During inspection, operate the machine according to standard procedures, then activate the reversing valve to fully extend the piston. At this limit position, the cylinder is in a lifted state.

Next, open the return oil port and observe whether any oil leaks. If leakage is found, inspect the seal for wear, and check the sealing ring between the piston and piston rod for integrity.

Replacing Damaged Seals and Support Rings

If the inspection reveals that the seal elements or guide support rings are damaged, they must be replaced with components of the same specifications and materials. This ensures compatibility with the original structure and helps minimize the oil film thickness between the sealing elements and surfaces—ultimately reducing the risk of repeated leakage.

Consequences of Poor Sealing in Hydraulic Cylinders

Poor sealing performance can lead to:

- Hydraulic oil leakage

- Unstable actuator movement

- Drop in volumetric efficiency

- Environmental contamination

- Inability to build pressure (system failure)

This is why it’s essential to inspect and maintain the sealing components regularly.

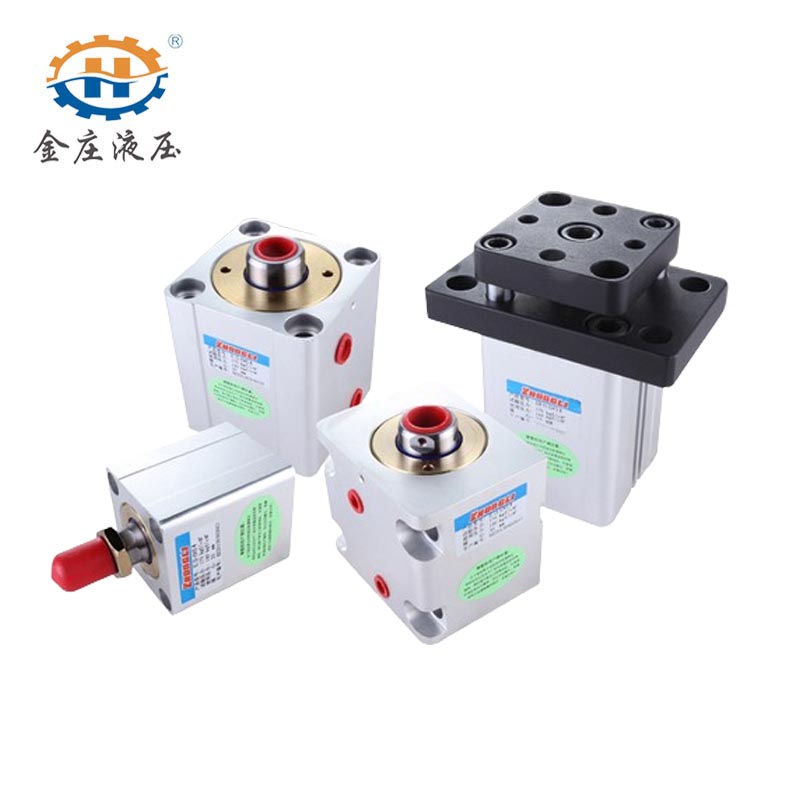

Advantages of Mechanical Hydraulic Cylinders

Mechanical hydraulic cylinders feature a simple structure and reliable performance. They can achieve smooth reciprocating motion without a deceleration mechanism or transmission gap, making them widely adopted in many hydraulic systems.

Corrosion and Contamination: The Hidden Risks

When used outdoors—in wind, rain, or freshwater environments—the risk of oxidation and corrosion increases. The presence of dirt, mixed particles, or moisture during manufacturing or assembly can worsen the problem.

Therefore, hydraulic cylinders with anti-rust properties should be selected for such conditions. Air and water leaks may also occur in these varied environments and require tailored solutions.

Pingback: What Is a Hydraulic Oil Pump? Functions, Types, and Key Features Explained - JinZhuang Hydraulic

Чрезвычайно полезная разбор, совсем в последнее время проверял информацию по

этой теме!!!

Thank you for your feedback. Your opinions are our greatest motivation!