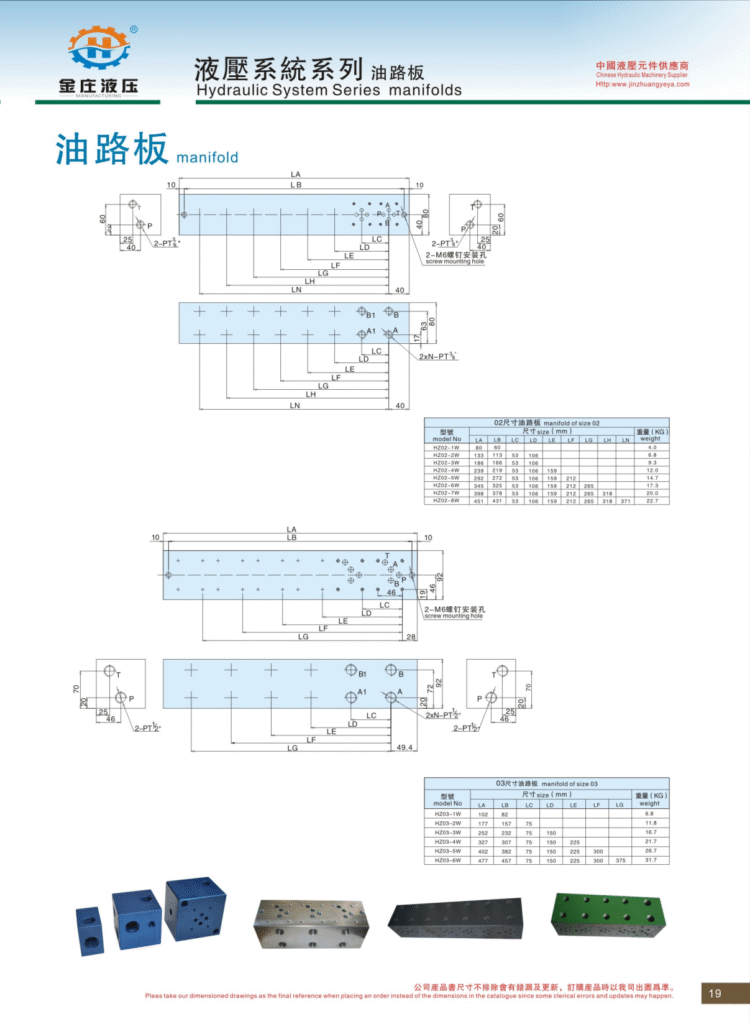

Hydraulic Manifold Block

High-quality hydraulic manifold blocks designed for efficient fluid control and multi-valve integration. Precision CNC machined and customizable for construction, automation, and industrial machinery.

Description

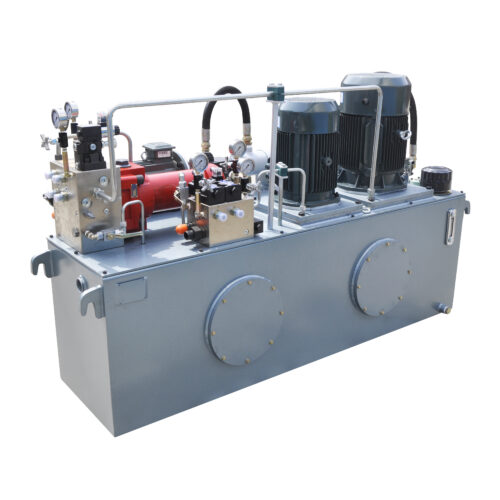

The hydraulic manifold block is a core component in hydraulic systems, used to integrate, distribute, and control fluid flow between pumps, actuators, and other components. It enables centralized valve installation by routing multiple hydraulic circuits within a compact metal block. This design reduces piping complexity, enhances efficiency, and minimizes leakage. Our manifold blocks are manufactured from high-strength carbon steel or aluminum alloy, and offer customization options for port layout, thread types, and flow configurations.

Key features:

-

Multi-channel integration for centralized fluid routing

-

High-quality materials: aluminum alloy or carbon steel for durability and corrosion resistance

-

CNC precision machining ensures accurate fit, reduced pressure drop, and zero leakage

-

Compatible with cartridge valves, modular valves, or solenoid valves

-

Customizable porting, mounting holes, and configurations

Advantages:

-

Simplifies hydraulic layout, reducing piping and saving installation space

-

Improves system response time and control precision

-

Minimizes potential leakage points, enhancing safety and reliability

-

Facilitates maintenance with modular construction

-

Reduces total system cost while improving integration and aesthetics

Application Scenarios:

-

Construction machinery – for centralized hydraulic control

-

Injection molding machines – to manage mold movements and actions

-

Industrial automation – for robotic arms and multi-axis controls

-

Aerospace and defense – for high-precision hydraulic control

-

Machine tools – integrated into clamping systems or hydraulic workbenches

Frequently Asked Questions (FAQ)

Q1: Can the manifold be customized to our system design?

A1: Yes, we provide complete customization services, including port positioning, thread specifications, and circuit layout.

Q2: Which material should I choose?

A2: Aluminum is ideal for medium-pressure systems and lightweight needs. Carbon steel is recommended for high-pressure, heavy-duty applications.

Q3: What types of valves can be mounted?

A3: Our manifolds support cartridge valves, sandwich valves, modular valves, and solenoid valves.

Q4: Do you offer technical drawings and design assistance?

A4: Yes, we provide 3D models, layout suggestions, and engineering support for optimal system integration.

Explore our other best-selling hydraulic products for different needs: Glycerin-filled Pressure Gauge、Hydraulic Valve Block.