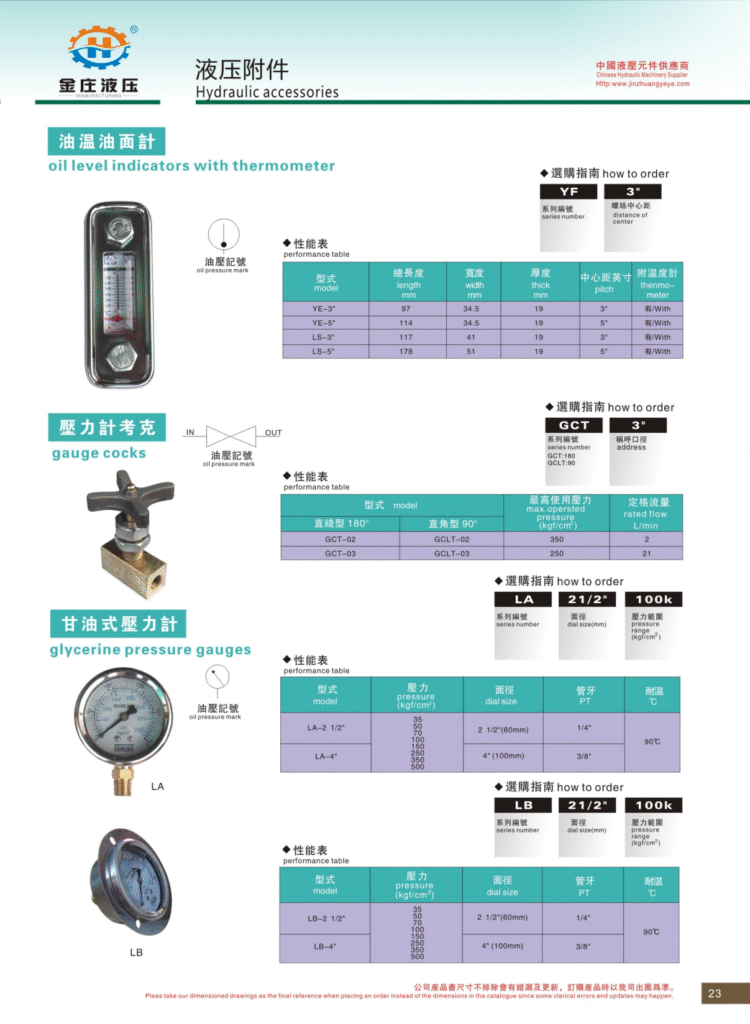

Glycerin-filled Pressure Gauge

Reliable glycerin-filled pressure gauge for hydraulic systems. Anti-vibration, corrosion-resistant, and built for precise pressure monitoring across industrial applications.

Description

The glycerin-filled pressure gauge is a widely used measuring instrument in hydraulic systems, designed to provide accurate and stable pressure readings even in high-vibration environments. By filling the gauge with glycerin, the internal mechanism is cushioned against pressure pulsations and mechanical shock, significantly enhancing the instrument’s durability and accuracy. With options in stainless steel or brass housing, this pressure gauge is ideal for harsh working conditions requiring reliable monitoring.

Key Features

-

Vibration Damping: Glycerin effectively absorbs vibration, protecting the internal gear mechanism and improving reading stability.

-

High Accuracy: Delivers precise pressure measurements with minimal deviation, making it ideal for precision-sensitive applications.

-

Material Options: Available in stainless steel, brass, or other alloys to suit various media and environments.

-

Versatile Mounting: Multiple thread connections (e.g., NPT, BSP) and mounting styles (bottom or rear) for diverse installation needs.

-

Clear Display: Large, easy-to-read dial face with bold markings for fast pressure reading.

Advantages

-

Extended Service Life: The lubricating effect of glycerin reduces wear on internal components, ensuring long-term use.

-

Excellent Corrosion Resistance: Constructed from corrosion-resistant materials, suitable for chemically aggressive fluids.

-

Operational Stability: Performs reliably under frequent pressure pulses or rapid system changes.

-

Broad Industry Application: Suitable for industrial machinery, hydraulic equipment, petrochemical facilities, and more.

Typical Applications

-

Hydraulic Systems: Monitor pressure in real-time to ensure optimal system function.

-

Construction Equipment: Integrated into loaders, excavators, and other heavy machines for pressure feedback.

-

Chemical Industry: Suitable for monitoring volatile or corrosive fluids under dynamic pressure conditions.

-

Food & Pharmaceutical Equipment: Available in food-grade stainless steel for clean environments.

FAQ

Q1: What makes a glycerin-filled pressure gauge better than a dry one?

A1: The glycerin filling minimizes vibration and provides smoother needle movement, improving reading accuracy and extending product life.

Q2: Can it withstand high temperatures?

A2: Standard models operate between -20°C to +60°C. For higher temperatures, special high-temperature variants are available.

Q3: Is there a risk of glycerin leakage?

A3: Under normal use, leakage is rare. If detected, it may result from shipping damage or wear and should be addressed promptly.

Q4: What dial sizes are available?

A4: Common sizes include 40mm, 63mm, and 100mm. Choose based on your installation space and readability requirements.

Explore our other best-selling hydraulic products for different needs: Pressure Gauge Cock、Vertical / Rear Mount Oil Level Indicator.